UHP900 • UHP1100 • UHP1300

Description

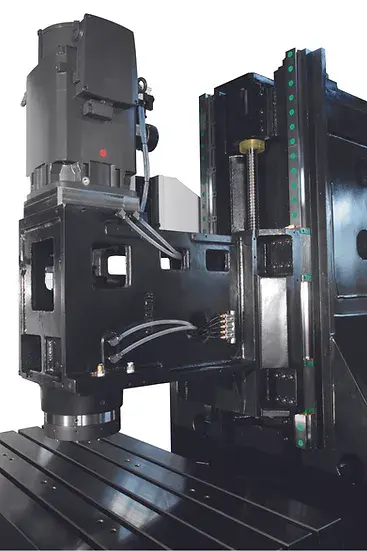

• The UHP series ultra-high performance centers are specially designed for high-speed and high-performance machining

• Advanced design with reinforced body structure through FEM analysis. UHP series offers excellent cutting performance and reduced vibration to meet the highest machining requirements

• Extra wide machine stand and base ensure high rigidity during high-speed movements

• Engine seat cooling circuit (UHP1100, UHP1300)

• Linear scales (option)

standard equipment

✔ Fully enclosed splash guard

✔ Spindle with direct drive 12000 rpm (UHP900)

✔ Direct drive spindle 15000 rpm (UHP1100, UHP1300)

✔ Tool changer with 24 stations

✔ Two screw and one chain chip conveyors (UHP 1100, UHP1300)

✔ Chip conveyor with chain (UHP900, UHP1500)

✔ Oil cooler for the spindle

✔ Air-conditioned control cabinet

✔ Cooling circuit for the engine seat (UHP1100, UHP1300)

✔ Rigid tap

✔ Ethernet, CF card and USB interface

✔ Automatic lubrication system

✔ Coolant system

✔ LED work light

✔ End of program light

✔ Electronic handwheel (MPG)

✔ toolbox

✔ Leveling bolts and blocks

✔ Coolant gun

✔ air pistol

✔ Blower when cutting

✔ User manual

Optional accessories

■ Built-in spindle HSK A63 20000rpm

■ 28-station arm tool changer

■40-station chain tool changer

■ IKZ cooling through the spindle + ATS

■ Oil cooling through the ball screw (only for UHP1100)

■ Oil scraper

■ Linear scales on X/Y/Z

■ 4th axis

■ 4th/5th axis

■ Workpiece measuring probe

■ Tool measuring probe

■ Additional 200GB SSD program memory (only available with SIEMENS control)